Wiring Update - Fuel Injected

5.0 into a '65 Mustang

Since installing this EFI system some 7 years ago, I was not happy with the amount of wiring left under the hood. The "Salt and Pepper" connectors created an unacceptable rat's nest.

Harness Modification Objective:

-

To remove as much excess wire as possible,

-

Eliminate "Salt and Pepper Shaker" connectors,

-

Reroute and include wires onto one run to the distributor

-

Clean and package neatly

Photo Explanation:

-

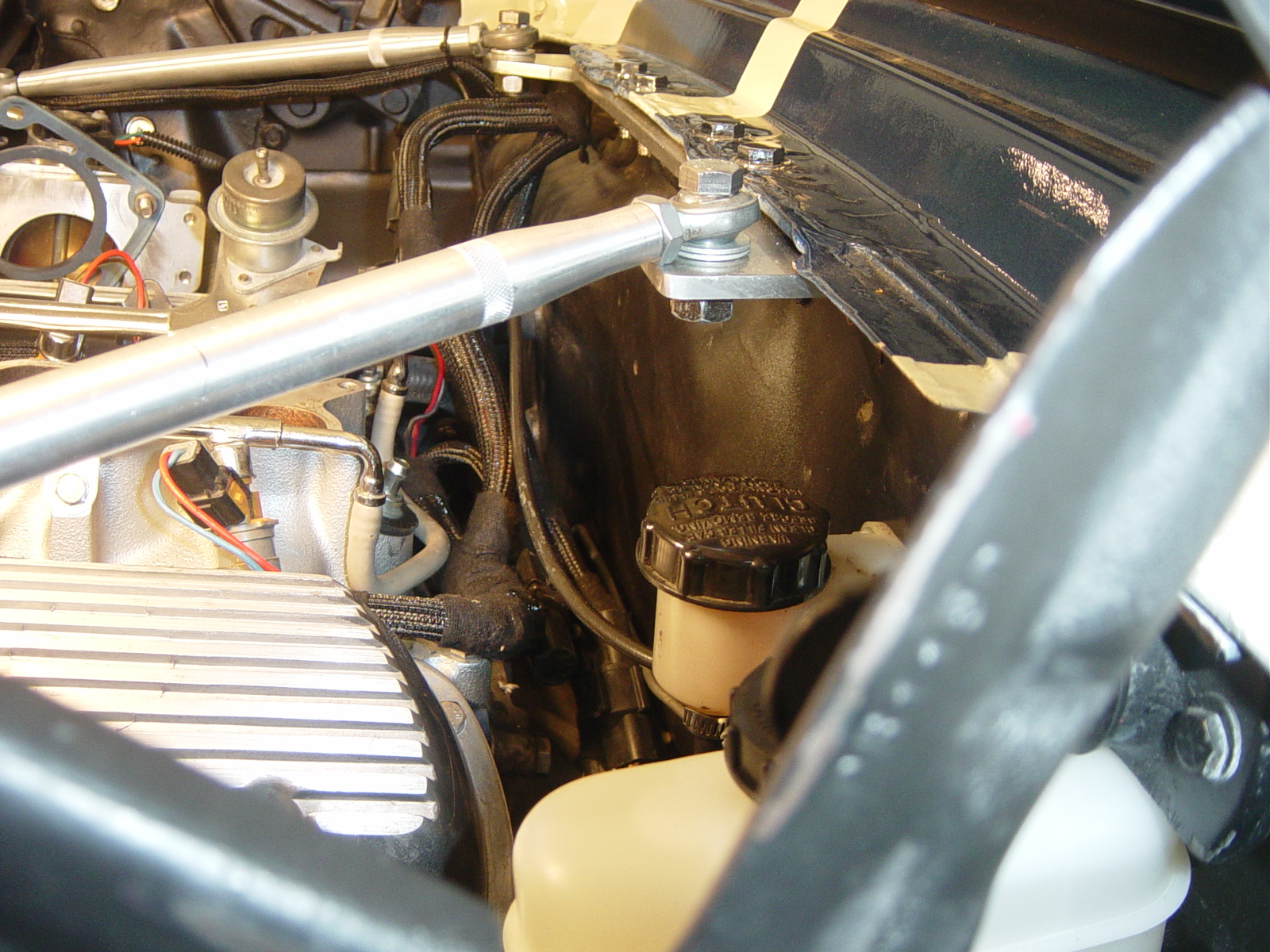

Finished engine bay with wiring neatly organized,

-

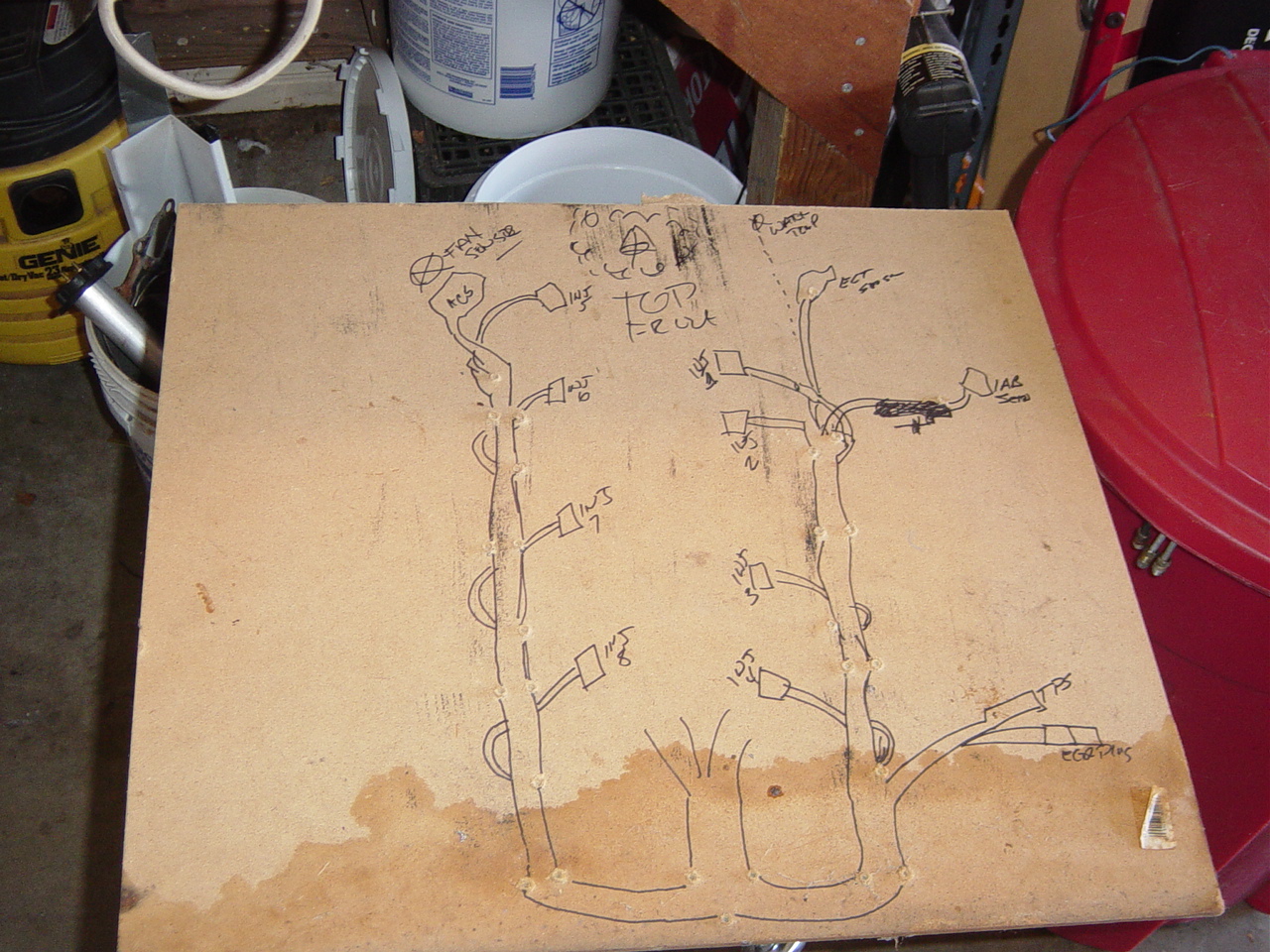

Wiring form board. The original engine harness was unwrapped, de-pinned from connectors and laid out on the board to coincide with the required component location. Nails were used as guides to align the harness during repackaging. Wiring for fan sensor added and water temp sensor relocated.

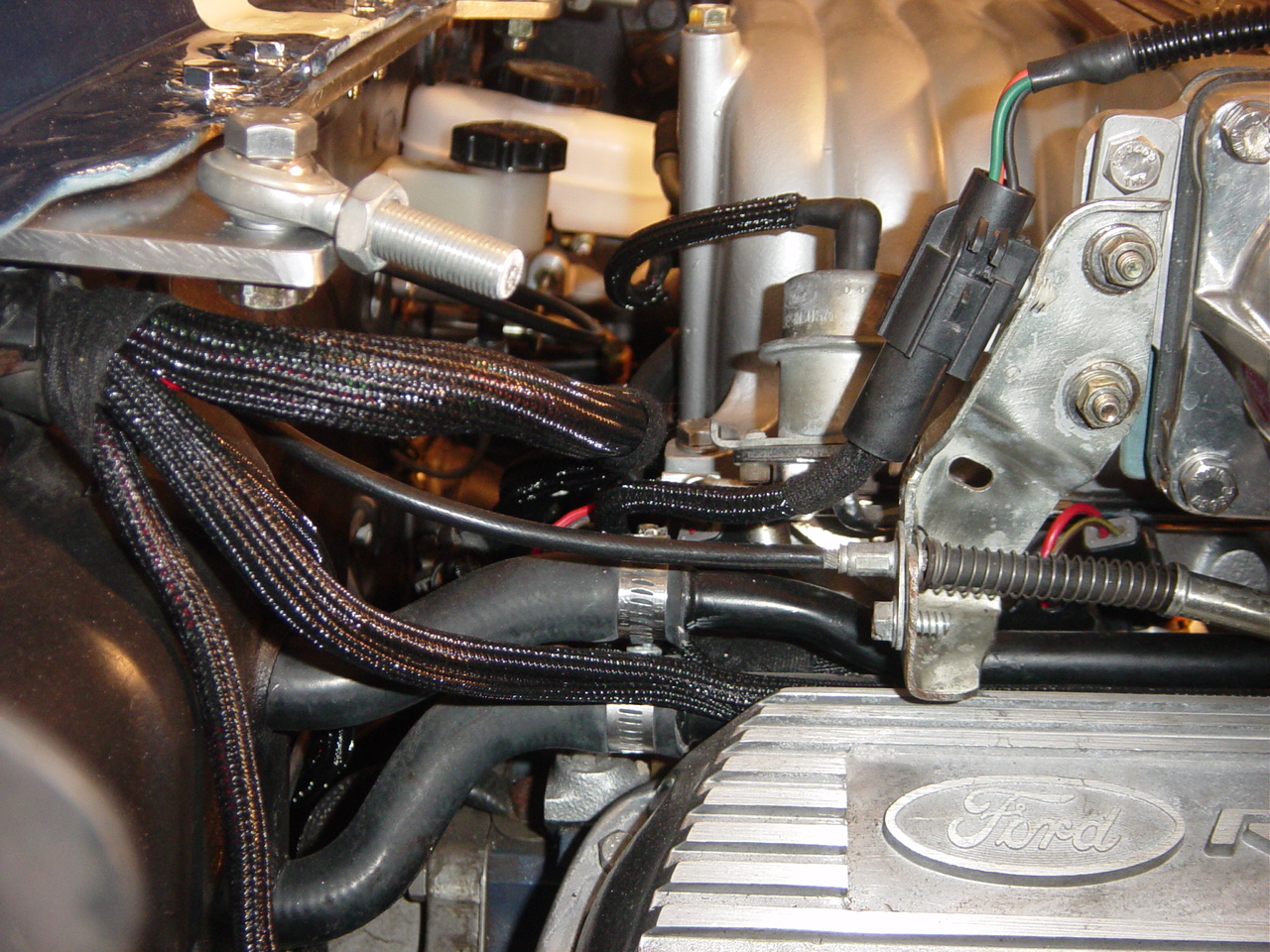

- Engine harness shown directly connected to the Computer harness with excess wire and connectors removed.

-

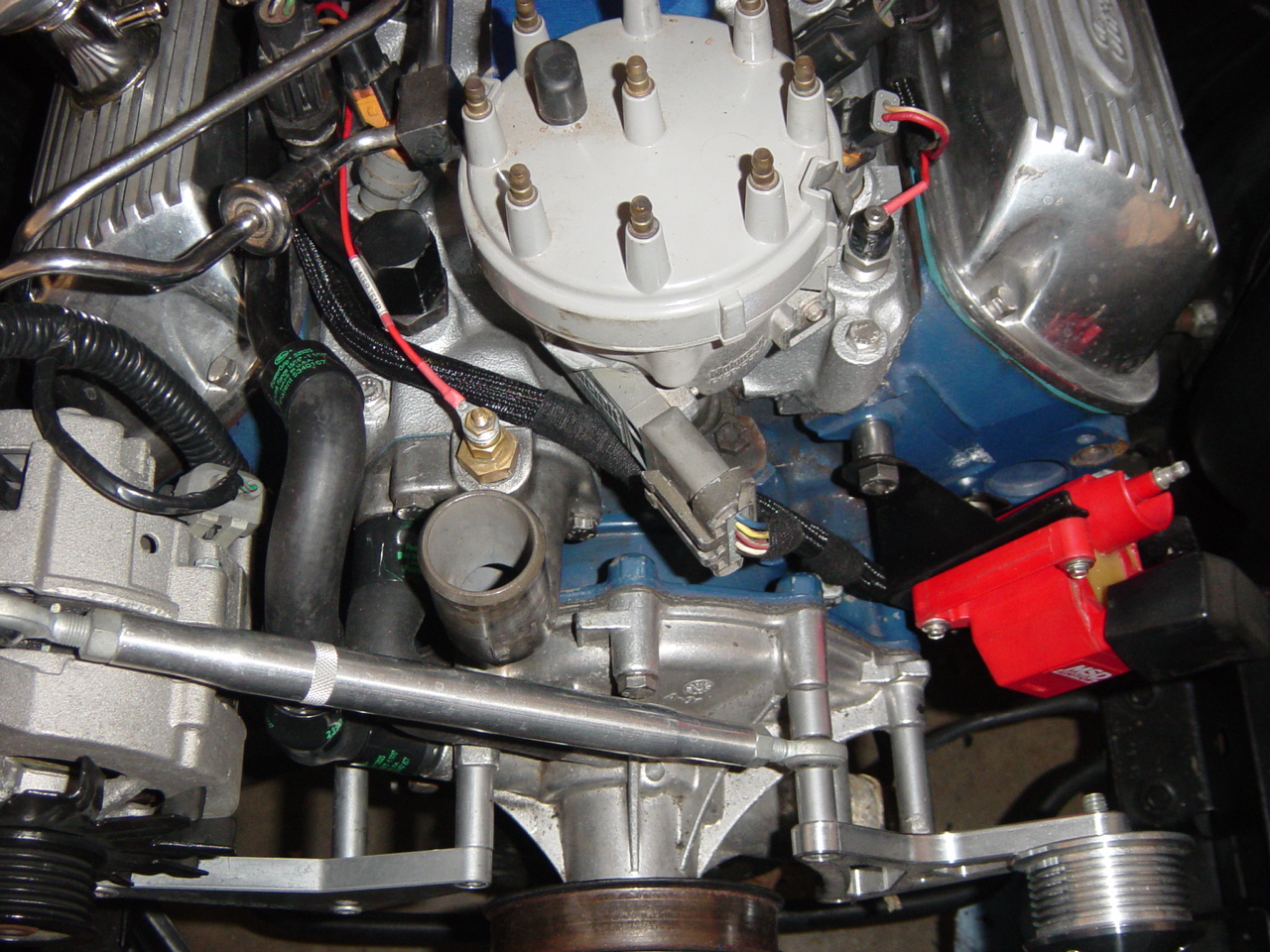

Fuzzy photo (sorry) showing layout over engine.

- Final wiring covered with expanded covering. Routing is 4 sub harnesses.

- Mass Air Sensor - (computer to air intake)

- Distributor wiring - (computer harness to distributor and coil)

- Injector wiring - (computer to injectors, ACT, ECT, electric fan, water temp, IAB, TPS and EGR plug

- O2 Sensor - (computer to

O2 sensor feed harness)

-

View of wiring across front of the motor for the Distributor, coil, and Oil sender.

The split braided

sleeving is made by Techflex, F6 brand, and comes in

various sizes. It is very similar to the Painless

"Powerbraid" loom but much cheaper. Search EBay

for 'Techflex'.

Photo 1

Photo 2

Photo 3

Photo 4

Photo 5

Photo 6