| In

order for a later model 5.0 to fit in an early

Mustang, either the oil pan needs to be changed or the

car's cross bracing/steering must be modified. I

chose the simpler and changed the motor's lower end

setup. Note the different in Early (64-72) and Late (79-95) Oil

pans. The rear sump of the late model interferes

with the cross member and steering. Required are a

replacement SBF 260-289-302 oil pan (Ebay for <$35),

and a new oil pump pickup tube/screen (Melling brand

pickup tube/screen is <$10 @ Autozone). The Oil Pump Pickup photo

below shows the Melling unit installed and ready for the

new pan.

While you're in there, you'll need to relocate

your oil dipstick from the side of the block to the

front timing chain cover. First remove the old

dipstick and discard. I used a wooden dowel to

seal off the old hole. After the pan was

installed, I tapped the wooden down in the hole and

left it. The dowel absorbs hot oil and seals off

the hole.

The dipstick must be relocated to the front of

the motor (Dipstick Location 1 below). This can

be done on or off the motor. Photos 2 and 3

below show where the boss exists in the cover. A

drill bit sized to the oil dipstick diameter is used

to drill out the boss and the oil pan

compartment. While I had the pan off, I cleaned

this corner of the pan/block with solvent, then masked

it off to ensure no shavings could migrate into the

lower end. (Pretty gutsy eh?) The motor bottom end was

taped off completely. After first drilling a

1/4" pilot hole, I stepped up to the correct diameter

bit. Care must be taken to ensure you establish

the correct angle so the dipstick tube can extend up

between the alternator and the head. Photo 4 below

shows the completed dipstick installation.

|

|

|

|

|

|

| Oil Pump Pickup |

Dipstick

Relocation 1 |

Dipstick

Relocation 2 |

Dipstick

Relocation 3 |

Dipstick

Relocation 4 |

Early Model Oil

Pan |

Recommend spending the extra few dollars and

buy the high quality 1 piece Felpro oil pan

gasket. This is a steel cored synthetic rubber

coated unit. You DON'T want your oil pan

leaking. When installing your new oil pan, make

sure your mating surfaces are perfectly clean, and the

gasket is clean. Use the plastic ears that come

with the gasket to hold it in place while

installing. Tip: SBFs tend to leak oil at the 4

corners where the tabs of the gasket slip into the slots around the fwd

& aft crankshaft journals. Use a

little RTV to seal off these corners.

| Motor mounts: The two photos

(right) show the two pieces of a 1966 motor

mount. The lower unit is bolted to the

shock tower frame, and the upper unit is secured

to the mounting holes on the side of the

block. When the motor is dropped into

place, a single bolt (shown in the first photo)

is inserted through the side which pins the

lower between the two sides of the upper. This

makes for a very easy installation. |

|

|

Headers/Exhaust/O2 Plumbing: The EEC requires HEGO (Heated Exhaust

Gas Oxygen) sensors to be mounted in the

exhaust system. These sensors monitor

the oxygen content of the exhaust and signal

the EEC as to the 'leanness' or 'richness' of

the exhaust. Threaded "Bungs" must be

welded into the exhaust system to screw

in the sensors. When stock early

model manifolds are used, the O2 sensor needs

to be welded into the exhaust pipe near the

attach point to the manifold. Late model

stock manifolds do not fit the early model

engine bay. I used Steve Ainsworth's (Ultrastang)

method of using 18mm spark plug anti-fouler as

the bungs to weld into my Hedman long tube

headers..

Instructions |

|

| Removal of EGR: Since I had removed all the smog items

from the 5.0, I also did not install

the EGR assembly (between the upper intake

and the throttle body). The EGR system is

designed to recycle burnt gasses

back into the intake for better emissions, and

an engine coolant circuit is used to cool the

intake. I removed the EGR

assembly from the end of the upper intake and

removed the threaded rods. I purchased a

1/2" billet aluminum spacer place, which

functions to block off the upper intake and also

to provide mounting points for the throttle

linkage bracket. This plate (right) was

purchased off Ebay for approx $20, and can be

found in various widths. I chose the 1/2"

width because I needed something as short as

possible in order to use the factory rubber MAF

snorkel.

Along with removing

the EGR assembly, the coolant lines must be

removed, and the two coolant ports

plugged. the rear intake port can use a

standard threaded plug. The forward line

attaches to the 3/8" port on the upper coolant

tube. I filled the port with high temp

RTV, and then installed a small rubber plug on

top and secured with a hose clamp. An

alternative is to braze shut.

The removal of the

EGR requires a "dummy signal" to fool the EEC

into thinking it is still in place. A EGR eliminator

plug can be purchased from

FordFuelInjection for approx $20, and will

complete the circuit and keep error codes from

being produced.

|

|

|

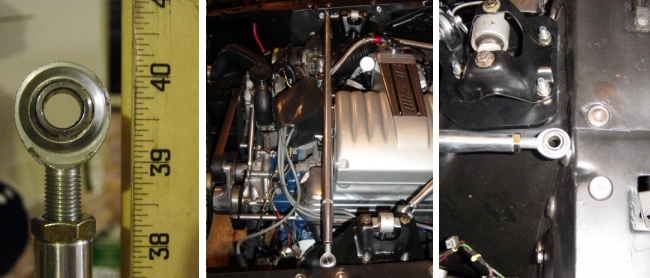

Throttle Linkage: The

factory 5.0 Mustang throttle linkage is a good

choice for the early model transplant. The

factory linkage is long enough to reach from the

throttle body on the passenger side (left photo)

to the proper location on the firewall over the

gas pedal (right photo). Note: Because the

EGR spacer was removed, the throttle body is

moved effectively 1.5" inboard. The

throttle attach bracket will not mount to the

billet spacer because it interferes with the

coolant tubes. The throttle attach bracket

must be modified to clear the obstructions. For a gas pedal, I used a standard 1970

pedal, and modified the upper end to reach the

throttle cable. |

|

| Serpentine Belt Mount: Note in the photos of the donor motor

above, there were no accessories. Kind of

a blank slate. There are SO many

choices regarding belts depending on what you

currently have, and what options your car

contains. Since I did not have A/C or PS,

I was left with the typical Alt-Crank-Water pump

triangle. Then the question becomes,

standard or reverse rotation water pump and V vs

Serp belt. Changing to a V belt would have

meant getting another harmonic balancer that was

correct weight with a 3 bolt pattern. It

also would have meant changing to a different

timing cover and a standard rotation water

pump. Too much cost. In the end, I

chose to leave the timing chain cover and

reverse rotation water pump as is, and run a OEM

serpentine path minus the AC, Smog, and P/S.

These missing items required the addition of an

alternator mount, and an idler pulley

mount. I chose a

March alternator mount and a

Trick Flow Idler pulley mount. March

makes both, but the Trick Flow is about 25%

cheaper. (But the March would have

matched). By using the TF

bracket, the idler pulley moves over to replace

the A/C and P/S pulleys in the circuit. I also installed a high volume polished

water pump. The belt is a Goodyear Gatorback; I

believe 59". Also, you will

need to get another Idler pulley that is

grooved. Check Summit for best

pricing on the brackets. |

|

Heater Hoses

|

Heater Hose

Routing: The donor 5.0 motor has the

standard metal heater tubes which run the length

of the pax side of the intake. This is a

much neater looking system than the old heater

hoses. To attach, I chose to use

pre-formed heater tubing to attach these lines

to the existing heater core, as well as clean up

the appearance of the installation. In the

top left photo, note the close positioning of

the tubes to the firewall. I took the area

measurements and headed to the local autoparts

store to cruise through the hose racks, looking

for suitable bends. After several tries I found

two hoses that had bends within them that fit

the situations. I took these, and cut out

the useable bends, and attached to the heater

tubes. This left a portion extending

inside the firewall. To connect to the

heater core, I used straight hose, with a

straight line coupling. (lower left

photo). In the end, the installation fit

very nicely. (Click photo at right for a

larger view). When choosing donor hoses

for their bends, choose carefully. The

formed hoses are expensive and the autoparts

store will not take them back once you've cut

them up. Update: Per Corky: Use a Gates

20662pn 90d 3/4-5/8 hose on the lower(3/4)

tube, then use a Gates 28625 90d 5/8x5/8 hose

connector to splice/connect the lower heater

hose coming from the firewall. The upper

heater hose can be used with no splice.

What a time & headache saver!! |

|

|

|

Radiator Hoses: Once again, installations will vary based

on the size/type of radiator and the upper

intake location. I have an AFCO aluminum radiator

installed, which moves the upper hose

location further to the passenger

side. I also use an in-line Tefba

filter to keep debris out of the

radiator. To mate the motor and

radiator, I used a standard Mustang 5.0

upper radiator hose, and spliced in the filter

at the most optimum point. Had I not had

the inline filter, I would have still used the

stock hose, but cut and inserted a piece of

steel tubing to adjust the distance. The

lower radiator hose outlet on my radiator is on

the driver's side (same as water pump). I

used a standard flex hose to fit. While

not as visually pleasing as the pre-formed

hoses, the universals come with a steel spring

which keeps them from choking down during a

strong coolant vacuum. |

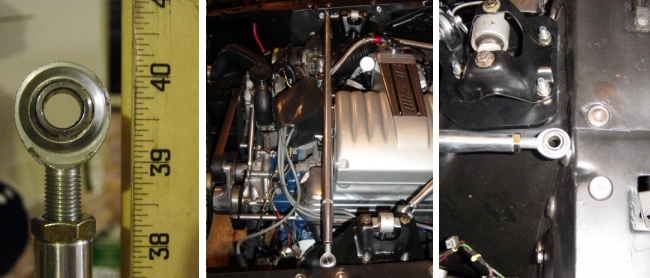

| Speedometer Cable Modification: In order

for the EEC to sense a deceleration condition, it has to be connected to the

transmission. Pins 3 and 6 of the EEC are

connected to the VSS, or Vehicle Speed

Sensor. This sensor is mounted to the

transmission end of the speedo cable. (See

photos right). To mount the VSS, remove

the plastic speedometer gear from the end of the

cable and cut off the end of the housing.

Some people cut off a portion and drill up the

end of the VSS to fit. I removed the total

end of the cable housing, leaving the end of the

speedomer cable. then I drilled a small hole in

the end of the VSS. This allowed me to

insert the end of the cable into the end of the

sensor to engage the internal mechanisms.

The to pieces are secured together using RTV and

a hose clamp. Lower right photo shows the

assembled parts. The plastic speedometer

gear is then reinstalled onto the end of the VSS

sensor. Note: If I was to get a 'do over',

I would leave approx 1/4" of the gear shaft, and

updrill the size of the interior housing to

mate. This would make for a more secure

alignment. Note…on an automatic

transmission, installation of VSS, is only

needed to prevent a code

Another option for

those who don't like cutting up there

speedometer cable is to purchase a completed

assembly from Ron Morris.

|

|

|

|

|

Accessories:

Starter:

Best to use the late model starter.

These PMGR "Mini-Starters" are very powerful,

very efficient, are smaller, lighter, and are

not prone to heat soak. It has ample

clearance from the long tube headers.

Installing a mini-starter requires modifying

the starter wiring.

K&N Air

Filter: Another nice option is

using a universal conical K&N filter (P/N

RE-0920). I have not oiled it yet, don't

want it clogging the MAF sensor.

|

|

|

Alternator

Wiring: Photos

at the left represent the 2G Alternator

installation. The alternator is a standard

2G 75 Amp unit. I am not worried about the

need for extreme power, as I am not running any

overly power hungry accessories. If I had

a large stereo, I'd want to install the

3G..

Diagrams of

connections, schematics, and connector views

are shown here.

The wiring is fairly straight forward.

In addition to using these schematics, I am

using a Ron Morris alternator

pigtail. It is a very high quality

product. I did however, end up modifying

the Ron Morris harness to this schematic.

In the near left

photo, you can see the alternator cable, the

175A Megafuse, and the connections to the

starter solenoid. The output side of the

solenoid now is connected to and fires the

solenoid mounted on the top of the starter.

|

| Export Brace and Monte Carlo

Bar: The

upper intake of the 5.0 will not clear the

standard bracing of a 1st generation

Mustang. The aftermarket export braces

will also interfere. There are several

options on the market, but I chose to build my

own as shown right. Detailed build

information can be found

here.

Detailed photos of

the custom Monte Carlo Bar are shown below.

|

|

| Reference Webpages: The

following webpages are good references and

support the details of the installation:

|

|

|